Laser beam fine focus analyzer

Darmin Catak – s011480

David Bue Pedersen – s031950

Preface

First and foremost we would like to acknowledge The Department of Manufacturing Engineering, the Technical University of Denmark, and CALM without whom this project would not be possible.

CALM is an abbreviation of Centre for applied laser micro manufacture, and the experiments within this project have been conducted in laboratories provided by CALM and IPL (Department of Manufacturing Engineering) at DTU (Technical University of Denmark). The laser used for the experiments is a fiber laser also provided by the Institute of Mechanical Engineering and Manufacturing, built by NKT research, also a CALM partner.

As well as providing the laser and laboratory, they have provided us with the necessary finances and all other equipment that has been needed to conduct the experiments and build our device.

Also we would like to thank Mr. Peter Carøe Nielsen, Mr. Jacob Nielsen and professor Mr. Fleming O. Olsen for their supervision and patience during the creation and completion of this project.

We would also like to thank Peter, Jakob and Flemming for giving us the opportunity to undertake this interesting project, and for providing us with the necessary literature and materials needed to understand and grasp the task that was given to us.

Denmark, Kgs. Lyngby, January 31 2007

______________________ ____________________________

Darmin Catak – s011480 David Bue Pedersen – s031950

Abstract

A method for monitoring and analyzing a laser beam is being researched. In this report one will be presented with the challenging task and the considerations that must be taken in order to monitor and construct a tool for analyzing the laser beam from an industrial laser.

Based on a known method presented in the 1983 by Lim G.C. and Steen W.M, Dept. of Metallurgy, Imperial College, London SW7, GB, it will be shown that it is possible to monitor a laser beam with a high resolution using a relatively simple approach.

Though this method back in 1983 was proven to provide inline feedback in the form of a beam intensity profile, the method was at the stage of discovery suffering from the lack of tools for strong numerical data processing and data logging.

Today these tools are readily available at an affordable price. An improved analyzing method based on the method of 1983 will be examined through a series of experiments. These will serve as a reference in the final development of a laser beam analyzer.

By using off-the-shelf electronic components a simple, yet advanced control system as well as driver software for the beam analyzer will be created which will aid in collecting analytical data through experiments. This will result in much better and more accurate datasets, than what is possible to achieve by collecting analytical data manually.

Through extensive mathematical analysis using numerical mathematical tools there will be developed a script based on existing source provided by Mr. Peter Carøe Nielsen. The script will be written in MatlabÒ by MathworksÒ and will have the ability to automatically process data from the analyzer during experiments.

This data processing procedure gives a good picture of how the laser beam propagates. These data then serve as an aid in the monitoring and assessing the quality of the laser beam.

Furthermore a mechanical structure will be created. It will contain all the subsystems the analyzer is made of. It will provide the ability to measure the laser beam from different angles around the path of propagation, and it will be designed in a manner so that it can be used to measure most industrial or experimental lasers.

The laser beam analyzer will be designed with ease-of–use in mind so that it can be operated after a short introduction. It will be able to be connected to any personal computer, and it will be able to execute measurement series unassisted by a human operator, thereby eliminating a possible source of error.

Finally the construction of the laser beam analyzer will be expected to be much cheaper in comparison to the purchase of most existing laser beam analyzers on the market today.

Table of contents

Preface........................................................................................................................... 1

Abstract.......................................................................................................................... 3

1. Background................................................................................................................ 7

2. Project definition......................................................................................................... 8

3. Main objectives.......................................................................................................... 8

4. Theory...................................................................................................................... 10

4.1 The beam analyzer explained............................................................................ 10

4.2 An introduction to laser optics............................................................................ 11

5. The Laser platform................................................................................................... 14

5.1 The 20 W fiber laser........................................................................................... 14

5.2 The Optical system............................................................................................ 15

5.3 The NC system.................................................................................................. 15

6. Initial experiments:................................................................................................... 16

6.1 Experimental setup............................................................................................ 17

6.3 Initial experimental considerations:.................................................................... 17

6.4 Resolution parameters:...................................................................................... 17

6.5 Theoretical minimal rotational speed.................................................................. 20

6.6 Equipment used................................................................................................. 22

6.6.1 The DC motor:............................................................................................ 22

6.6.2 The reflective rod and fitting........................................................................ 22

6.6.3 The detector................................................................................................ 22

6.6.4 The beam dump.......................................................................................... 24

6.6.5 The vision system....................................................................................... 24

6.6.6 The oscilloscope:........................................................................................ 24

6.7 Other equipment used during the initial experiments......................................... 25

6.8 Experimental approach...................................................................................... 26

6.9 Experimental procedures................................................................................... 26

6.10 Commonly routines and commonly used parameters:.................................... 28

6.11 Experimental overview:.................................................................................... 29

6.12 Experiment 1:................................................................................................... 30

6.13 Experiment 2:................................................................................................... 31

6.14 Experiment 3:................................................................................................... 31

6.15 Experiment 4:................................................................................................... 32

6.16 Data post processing....................................................................................... 34

6.16.1 Needed data.............................................................................................. 34

6.16.2 Determining the Gaussian........................................................................ 34

6.16.3 Calculating the beam propagation path..................................................... 37

6.17 Presentation of data from the initial experiments............................................. 39

6.17.1 Experiment 1............................................................................................. 39

6.17.2 Experiment 2............................................................................................. 41

6.17.3 Experiment 3............................................................................................. 45

6.18.4 Experiment 4............................................................................................. 46

6.18 Conclusion of the initial experiments................................................................ 47

7 Designing the beam analyzer................................................................................... 49

7.1 The first design concepts:................................................................................. 50

7.2 The final design:................................................................................................. 53

7.2.1 The turntable and horizontal plate............................................................... 53

7.2.2 The ball bearing unit.................................................................................... 54

7.2.3 The back plate............................................................................................ 56

7.2.4 Reflector rod holder.................................................................................... 56

7.2.5 The reflector rod......................................................................................... 58

7.2.6 The inverted T-frame skeleton................................................................... 59

7.2.7 Spindle and linear motion rail....................................................................... 59

7.2.8 Strength of the turntable plane.................................................................... 60

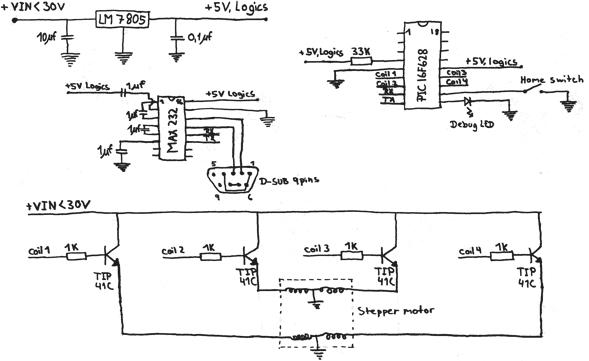

7.3 Electronic components and mechatronics........................................................ 63

7.3.1 The power supply....................................................................................... 63

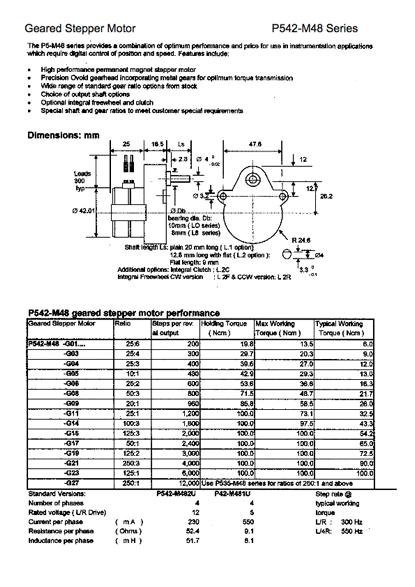

7.3.2 Stepper motor............................................................................................. 63

7.3.3 Stepper motor controller............................................................................. 65

7.3.4 Brushless motor and controller................................................................... 68

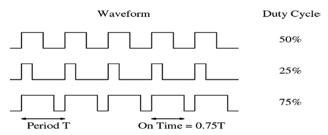

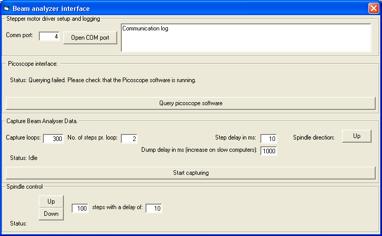

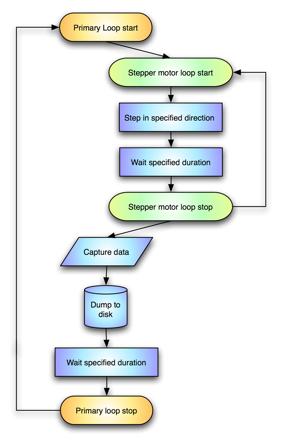

7.3.5 Beam analyzer controller software:............................................................ 70

7.3.6 REV counting mechanism........................................................................... 73

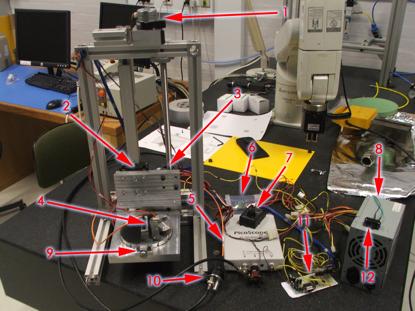

8 The finished laser beam analyzer............................................................................. 75

9 Economic overview................................................................................................... 77

10 Validating the laser beam analyzer......................................................................... 77

10.1 Measurement set 1.......................................................................................... 77

10.1.1 Measurement data 6A:.............................................................................. 78

10.1.2 Measurement data at 5.5A........................................................................ 80

10.1.3 Measurement data at 5A........................................................................... 82

10.2 Conclusion of the validation experiments.................................................... 84

10.3 Hunting the distortion problem......................................................................... 85

11 Error identification................................................................................................... 87

11.1 Human errors................................................................................................... 87

11.2 Reflector rod.................................................................................................... 87

11.3 Rotational speed.............................................................................................. 87

11.4 Cladding mode................................................................................................. 87

12 Conclusion.............................................................................................................. 89

13 Future work............................................................................................................. 90

14 References............................................................................................................. 91

15 Appendices............................................................................................................. 92

15.1 The documentation CD-ROM.......................................................................... 92

15.2 Matlab script..................................................................................................... 92

15.2.1 Gauss_fit.m............................................................................................... 92

15.2.2 beam_propagation.m................................................................................ 95

15.2.3 Support functions for the matlab script..................................................... 95

15.3 Stepper motor controller schematics............................................................... 97

15.4 Stepper motor controller firmware code.......................................................... 98

15.5 Stepper motor data sheet.............................................................................. 102

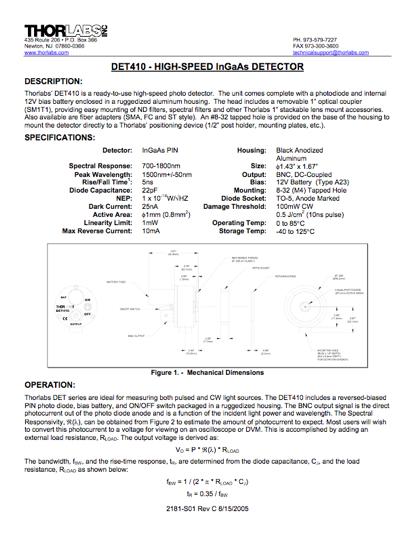

15.6 Detector datasheet........................................................................................ 103

15.7 SKF 61819 ball bearing datasheet................................................................. 104

15.8 Parts and costs.............................................................................................. 105

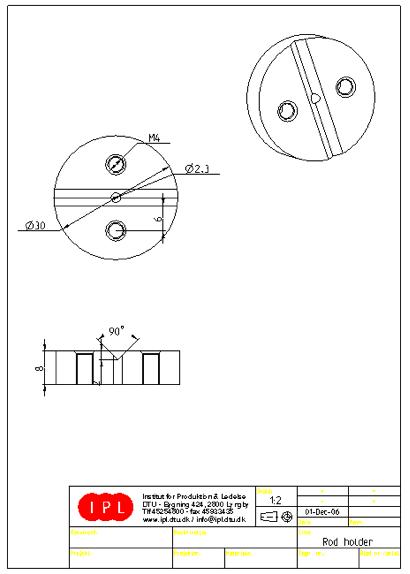

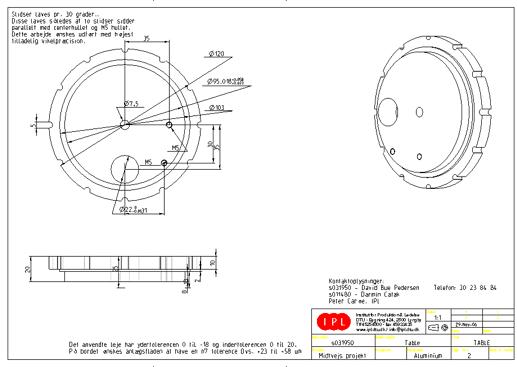

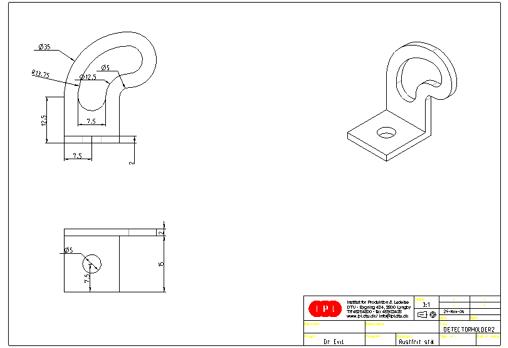

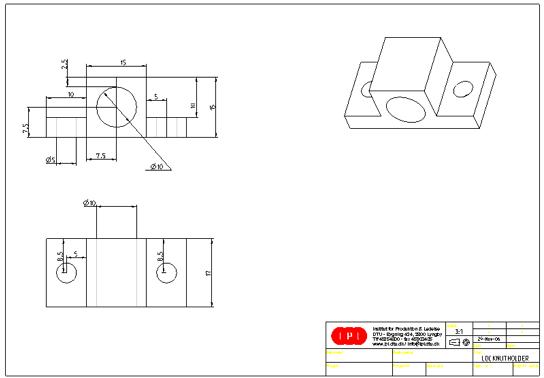

15.9 Technical drawings........................................................................................ 107

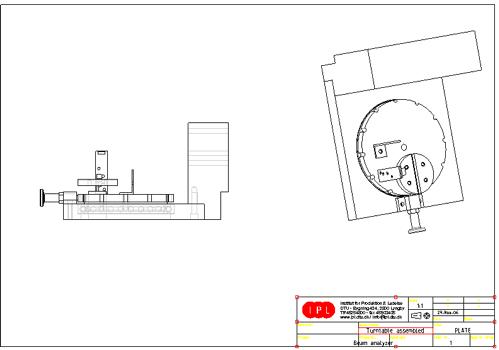

15.9.1 Turntable overview................................................................................. 107

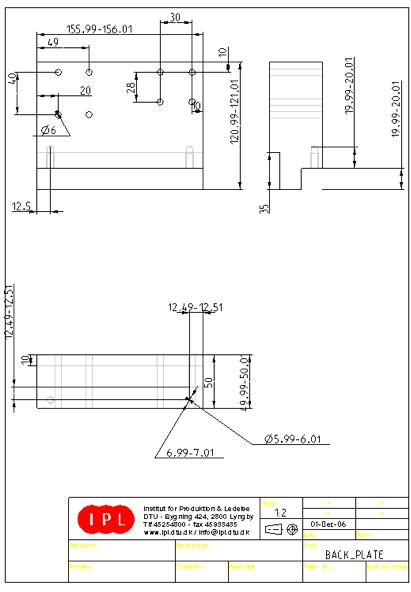

15.9.3 Back plate............................................................................................... 108

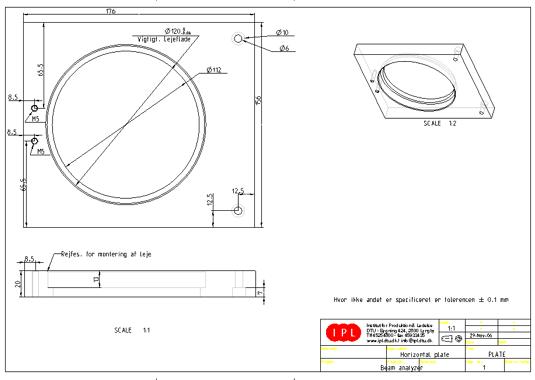

15.9.3 Turntable plate........................................................................................ 109

15.9.4 Reflector rod fitting.................................................................................. 110

15.9.5 Turntable................................................................................................. 111

15.9.6 Detector holder....................................................................................... 112

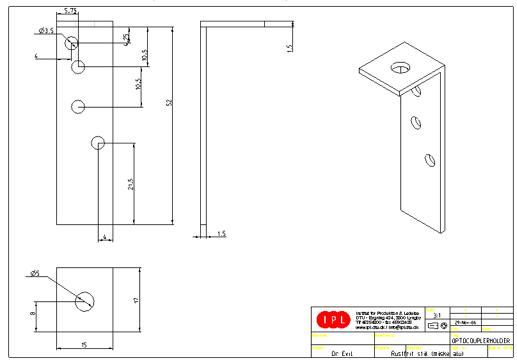

15.10 Optocoupler holder.................................................................................. 114

15.9 Tolerance chart.............................................................................................. 115

1. Background

In 1983 an article describing a laser beam analyzing method was published[1]. The force of the method seemed to be the simplicity of the experimental setup and the ability of monitoring the intensity profile and spot size of a high power laser directly in the focus of the laser beam.

When using high power laser beams for industrial or research purposes it is very important that the process is monitored either in-process or offline.[2]

Depending on the laser process, different characteristics of the beam itself need to be maintained. For example in laser welding or cutting, it is needed that the beam penetration is very narrow and deep. To make sure this is possible a finely formed beam with large depth of focus is needed.[3] This is just one of the processes that requires monitoring, to make sure that the quality of the process, in this case the weld or cut, is kept. In other processes different characteristics are needed, but the monitoring is still very important if the quality is to be insured.

General perception of the laser beam is that its profile always stays constant, and that the laser system will always produce perfectly coherent results. However this is not true. Also written in the 1983-article is mentioned that it has been proven that if this consistency is to be kept then frequent analyzing of the beam is needed.

The basic principles behind the beam analyzing method and the optics involved will be further explained throughout the report.

2. Project definition

The project forming the foundation for this rapport has the purpose of developing a beam analyzer that can measure the beam propagation of an industrial or experimental fiber laser.

The laser beam analyzer must be based on the principles described in the article from 1983 [1]. The final goal is to be able to describe a series of beam parameters such as parameters that describe the beam propagation path, and the intensity distribution over the beam.

To construct the measuring equipment following work must be undertaken:

- The underlying theory must be understood. This theory will form the knowledge base of the math and physics that will be used throughout the project.

- Replication of the experimental setup from 1983 is needed for a proof-of-concept, and these initial analytical data will be used to define the further design requirements for the beam analyzer.

- A data processing method will be developed. This will consist of the development of a numerical MatlabÒ script that will be used to process data from the beam analyzer.

- A prototyping phase will be undertaken where possible beam analyzer designs are examined after which a final design is to be selected.

- The manufacturing of the parts used in the beam analyzer will be ordered. Some parts is produced by the project team, and assembly of the laser beam will be undertaken.

- Experimental work on the developed beam analyzer will be done for validation.

- Finally the project will be documented in the form of the report you are currently reading.

3. Main objectives

The main objective of this project is to be able to measure the spot size at the focal point for lasers with a spot size down to of 10 µm. Only one geometrical binding has been requested by the IPL/CALM group. It is that the beam analyzer must be able to fit underneath a laser system with 50-70 mm clearance from the substructure to the laser nozzle.

Finally the beam analyzer must be developed with simplicity in mind and the budget of the laser beam analyzer must not exceed 2,000 $

Experiments conducted in the preliminary experimental work will define further demands and requirements that need to be abided for the beam analyzer to perform as desired. Final tests on the finished beam analyzer will show if these demands have been met.

4. Theory

After a brief explanation of the working principle of the laser beam analyzer, the theory and optics that is used throughout the report will be explained

4.1 The beam analyzer explained

The mechanism of the laser beam analyzer described in the 1983 article[1] is very similar to what is seen in a supermarket bar-code reader. A laser beam is by a mechanism scanned over a detector. The detector delivers an output voltage representing the intensity of the light hitting the detector window. A barcode reader uses the intensity peaks received between the black lines in the bar code to read a binary code. The laser beam analyzer uses the output signal to measure the intensity distribution of the laser beam.

In a barcode reader a low powered laser diode < 5 mW are scanned over the barcode by a rotating mirror, and it is the reflections from the barcode that provides the signal. In the laser beam analyzer, the laser beam is reflected by a highly reflective rod rotating at high velocity trough the focus of the laser beam. As the rod travels trough the laser beam it is scanned directly over the detector that reads the intensity profile of the signal.

4.2 An introduction to laser optics

The model that most people have in mind when thinking of optics is a very simplified model descending back to childhood experiences with a magnifying glass used to focus the sunrays. The model states that a parallel bundle of sunrays are focused in an angle defined by the lens and that there is one clearly defined focal point in where the area of the beam spot is close to zero. This model is extremely simplified compared to what happens in reality. Light from a laser never propagates truly parallel, and diffraction sets a limit on how small a spot can be focused[4].

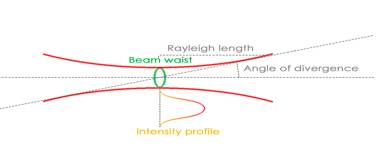

The beam close to the focal point has the shape seen on figure 4.1. The beam waist is defined as the smallest radii of the beam throughout the path of propagation.[5] Even though this is called the focal point, it is easily seen that the beam radii changes slowly close to focus, and that the intensity of the beam in this area is almost as high at the waist position. This focal range is also called the Rayleigh Length[6].

The following optical parameters will be discussed:

Beam waist: [w0]

Rayleigh length: [zr]

Angle of divergence: [q]

Beam quality: [M2]

Figure 4.2.1 profile of the laser beam

Another common statement is the fact that a beam can be parallel. There is no such thing as a parallel beam. A beam bundle that starts as being parallel will further down the beam path slowly diverge due to diffraction. Diffraction is the phenomenon that a parallel beam bundle will spread as it propagates, much like the phenomenon that occurs when observing the backscattered waves as they roll back in a spreading formation after a wave front hits an offshore structure in the water. Furthermore there is a relation between wavelength and diffraction. For shorter wavelengths the diffraction is decreased.[7]

The diffraction phenomenon is linked to another important parameter: The angle of divergence. This angle explains how hard the laser beam is focused and is defined from classic ray tracking. A hard focused beam has a high angle of divergence, and can focus to a smaller spot size than a beam with a smaller angle of divergence. The limit for how hard a laser beam can be focused is called the diffraction limitation phenomena[8].

The parameters described so far can now be used to describe one of the most important parameters in the world of lasers. This is the M2 value[9]. This value is defined as the parameter for quantifying the beam quality of laser beams, and its form is seen in formula 4.1:

(Formula 4.2.1)

(Formula 4.2.1)

Where [q] is the angle of divergence, [l] is the wavelength of the laser and [w0] is the beam waist.

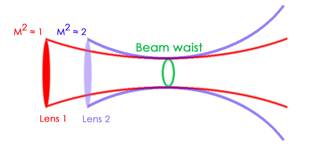

The relation between M2 and beam quality is that for higher quality M2 ® 1. This can be explained in the following way. Assume that there are two lasers. Laser #1 with M2 ≈ 1 and laser #2 with M2 ≈ 2. They must be focused to the same spot size with same diameter of the focus lens. To obtain this, laser #2 must be focused harder than laser #1 This affects the position of the waist as it will be moved closer to the lens for laser #2 than laser #1.

Figure 4.2.1 The relation between beam focusability and M2

Finally the Rayleigh length will be defined. The Rayleigh length is the distance from the beam waist at which the mode area is doubled. This is expressed with the following relation[6]:

![]() (Formula

4.2.2)

(Formula

4.2.2)

Where [wr] is the waist at the Rayleigh length and [w0] is the beam waist.

The Rayleigh length for a diffraction limited optical system is given by the expression:

![]() (Formula

4.2.3)

(Formula

4.2.3)

[zs] is the Rayleigh length, [w0] is the beam waist and l is the wavelength.

If it is assumed that M2 equals 1, the mode of the beam is a pure TEM00 mode.[10] This means that the beam spot has the shape as seen on figure 4.3.

Figure 4.2.3 The shape of a TEM00 beam spot

The TEM00 mode is called the fundamental mode. The intensity profile across this mode is characterized by being a Gaussian distribution. For higher order modes this does not apply but the lasers used during all the experimental work which forms the basis of this thesis have a small M2 value, almost a TEM00 mode and hence a close-to-Gaussian intensity distribution[11].

The theoretically intensity profile for the fiber laser that was used during the experimental work is shown in the lower part of figure 1. It is a Gaussian distribution[11] following formula 4.4:

![]() (Formula

4.2.4)

(Formula

4.2.4)

Where the constants are real as well as: a > 0, b, and c

This completes the optical theory used within the thesis and will be referred to when needed.

5. The Laser platform.

5.1 The 20 W fiber laser

The test subject in throughout the project is a mid-range 20 W fiber laser. This is suited and used for a wide range of experimental work. It is built into a safety cabinet making it a class I laser system, which means that anybody with a short briefing can use this laser.

20 W describes the maximal output power of the laser. Though 20 W isn’t much compared to high-power lasers this laser is far from weak when it comes to power density as the pure mode of the laser gives great focusability[figure 4.2.1].

The determining factor for the quality of the fibre lasers are the type op fibre used in the laser. Single mode fibre lasers are known for a very pure and good mode because the output fibre only allows one mode to travel trough. This gives an unmatched M2 and makes the beam easy to focus.

Specifications provided by the manufacturer[12]:

CW Ytterbium doped fiber module

5-20W output power

Max current 6 A

Effect/Current rating of 3.47W/A.

Single mode fiber delivery

Diffraction limited output

M2< 1.1 (The CALM laser is a prototype hence M2 < 1.2)

Power vs. input current is linear.t

Fixed central wavelength between 1060-1090 nm (The CALM laser has been measured to 1075 nm)

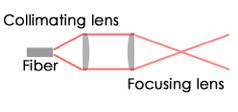

5.2 The Optical system

The optical delivery system consists are built up a follows: A SMA connection connects the output fiber from the laser to a collimator. The beam leaves the fiber as it propagates towards infinity at a at a known widening angle. At a desired width the beam are collimated. The Collimator is a convex lens as seen on figure 5.2.1, that is used to redirect the beam so it propagates in a close-to-straight path and the distance from the fiber to the collimating lens is the focal length of the collimating lens[13].

Figure 5.2.1 Optical system

When the beam is collimated it is ready to be focused. This is done by the focusing lens. The specifications of the optical system used is as follows:

- Collimator: Focal length = 35.9 mm (red light), The diameter is oversized.

- Focus lens: Focal length = 75.0 mm (red light), The diameter is oversized.

- Estimated minimum waist: 8-9 mm

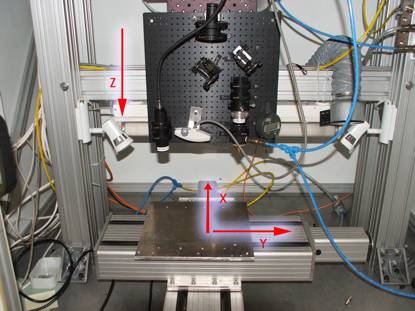

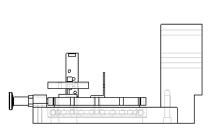

5.3 The NC system

The laser is mounted in an NC setup. It is a 3 axis system with movement in the vertical and horizontal plane.

The NC table has two vertical axis called X and Y and a horizontal axis called Z. The X- and Y-axis are combined in a base structure and the Z axis is placed on a frame above the former axes. An overview can be seen on picture 5.3.1

Figure 5.3.1 Axes of the NC system

The resolution of the NC setup is relevant since initial testing will rely on the resolution of all the axes. The resolution is seen in table 5.3.1.

|

Axis |

Backlash [µm] |

Pitch [mm/turn] |

Min. step size [µm] |

|

X |

3,5 |

5,003 |

12,5 |

|

Y |

4,1 |

4,997 |

12,5 |

|

Z |

3,75 |

2,500 |

6,25 |

Table 5.3.1 Resolution of the NC system.

The NC software used to control both laser and the NC system has its origin as a milling NC software. It has been adapted in such a way that the commands used to control the movement of the milling tool spindle will be used to control the laser instead. Hence the spindle speed controls are used to control the power of the fiber laser.

Due to the fact that many lasers are missing a horizontal axis a similar 1 axis NC control system may be implemented in development of the beam analyzer to accommodate the need for such an axis.

6. Initial experiments:

Before development of the laser beam analyzer can be initiated it is necessary to replicate the experiments conducted in 1983. This is done in the CALM/IPL laboratory on the 20W fiber laser.

6.1 Experimental setup

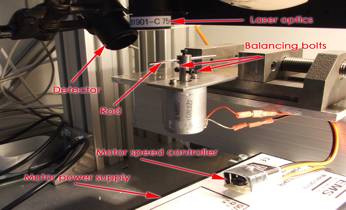

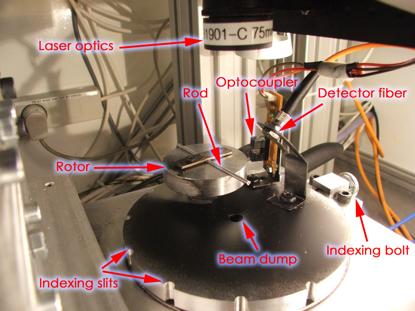

The experimental setup is very simple. A thin highly reflective rod is connected perpendicular to the axis of revolution of a miniature DC motor.

The dc motor is set to spin in a path perpendicular trough the laser beam.

Finally a detector coupled with a multimode mode 800 mm fiber is placed at roughly a 45 degrees angle above the rod and motor in such a manner that the laser beam will be scanned over the detector.

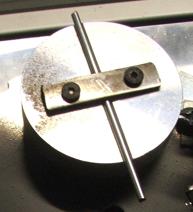

Picture 6.2.1 shows this simple setup what is used in the initial experiments:

Picture 6.2.1 Initial experimental setup.

6.3 Initial experimental considerations:

Lasers with different wavelengths as well as power density can be analyzed using the initial setup. There are three major areas of concern though.

The detector must be chosen to match the wavelength of the laser. The rod must be selected so that it reflects the wavelength. The speed of the rod must be so fast that the thread doesn’t take any damage by exposure from the laser beam, and hence the detector must have a rise/fall time that allows the needed rotational speed. A thorough explanation on this subject will be given in chapter 6.5.

6.4 Resolution parameters:

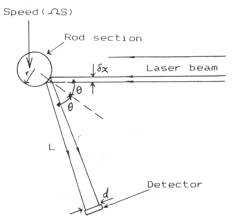

Related to the detecting mechanism is the diameter of the spinning rod, the area of the detector and its positioning in the respect to the plane of rotation of the rod. These are factors that will influence the measuring resolution of the arrangement. The governing equation for this[1] is formula 6.4.1:

![]() (Formula 6.4.1)

(Formula 6.4.1)

The symbol explanation is as follows. r is distance from the rotational center of the rod to the measurement point. d is the diameter of the detector. l is the distance from the rod to the detector. q is the angle in which the detector is positioned. dx is the resolution. The different parameters are graphically represented in figure 6.4.1.

Figure 6.4.1 Parameters related to formula 6.4.1

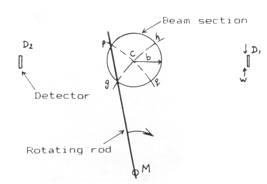

As the rod travels across the path of the beam, it will scanned over the detector which will give a response in form of an output voltage. This voltage corresponds to the beam intensity profile or power distribution. At any moment in time, the output voltage is proportional to the average power over an area defined by wδx where w is the length of the detector window in the direction of the length of the rod. This is visualized in figure 6.4.2

Figure 6.4.2 Graphical representation of wδx being the window of the detector

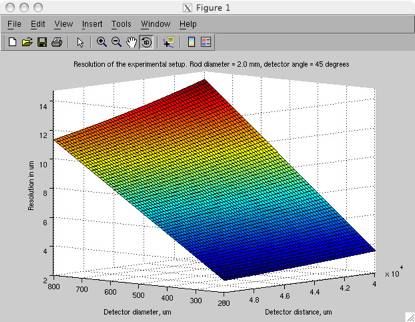

The governing equation is not only useful for calculating the resolution but also very useful when defining an operational range. Knowing the resolution it becomes possible to optimize the other parameters being rod radius, measuring distance from rotational center, measuring angle and diameter of the detector window. By using simple mathematical algorithms one can generate a 3 dimensional graph in which one can find an optimal range of operation for any resolution. This means one can find a given set of parameters (r, d, l, and theta) for any known resolution, as seen on figure 6.4.3.

Figure 6.4.3 shows the resolution 3D graph

This graph is made for a constant rod radius, and for a constant angle theta. It turns out that if one wants to manipulate all the parameters then the algorithm becomes more complicated, and the shear amount of data makes it difficult to present a visualization of the relations between parameters. Dark blue area is the area of interest for the experiments as this area provides the best resolution.

6.5 Theoretical minimal rotational speed

The speed of the rotation must not be too small or too great. If the speed is too small the laser will simply cut an indent in the rod. However if the speed is too great the detector, will not be able to sample the data correctly as it’s rise/fall time will be exceeded, and the true characteristics of the beam will not be known.

A lower limit of the rotational speed of the thread due to melting/vaporization damage to the thread can be calculated. This speed tells the user of the beam analyzer at which speed the thread should rotate on any given laser setup. The theoretical value will also be compared to experimental results found on the 20W fibre laser used for the experiments.

The following values are assumed:

Laser: 20W.

Laser spot size: 0.03 mm radius.

Thread material: Aluminium

Reflector rod radii: 0.250 cm

Distance, measuring point - rotational centre: 3.5 cm

First of all the following material data for aluminium are used [www.matweb.com]:

Coefficient for light coupling into the material: ![]()

Thermal conductivity: ![]()

Heat capacity, solid phase: ![]()

Density: ![]()

Maximal allowed temperature: ![]()

Thermal diffusivity: ![]()

The maximal allowed exposure time for the thread with the given parameters can now be calculated from formula 6.5.1 which is derived from W. M. Steen, Laser material processing, third edition, formula (3.2).

![]() (Formula 6.5.1)

(Formula 6.5.1)

Where F0 is the absorbed power density:

![]() (Formula 6.5.2)

(Formula 6.5.2)

Now tmax can be found:

The minimal rotational speed can finally be calculated:

![]()

This theoretically lowest rotational speed are used as an indicator of how slow the reflector rod can rotate without taking damage

6.6 Equipment used

6.6.1 The DC motor:

The DC motor used to rotate the thread was and OEM bulk DC motor with unknown specifications. The maximal rotational speed was well above 17.000 RPM though. The motor is fixated with a vise and positioned on the X-Y planes of the NC system.

6.6.2 The reflective rod and fitting

The reflective rod that is mounted on the DC motor is held in place by an aluminum fitting turned on a lathe in a student’s metal workshop located on Campus at DTU. A rough balancing mechanism has been built into the fitting so that it has a symmetrical plane through the axis of revolution. It can be seen in Picture 6.2.1. The reflective rod itself is cut of an aluminum TIG welding filler rod, since the coupling of the laser light into aluminum at a wavelength of 1075 nm is very low as seen on fig 6.6.2.1.

Figure 6.6.2.1 Reflectivity of rod material[14]

6.6.3 The detector

The detector type is chosen depending on the wavelength of the beam, so that it matches the type of laser being analyzed. To solve this problem the simplicity of the device allows it to have an indefinite range in regards to the detectors, by simply interchanging the fiber attachment to the detector.

The detector used during the experimental work has been produced by Thorlabs and has the following specifications:

Detector: InGaAs PIN

Housing: Black Anodized Aluminum

Spectral Response: 700-1800nm

Size: φ1.43” x 1.67”

Peak Wavelength: 1500nm+/-50nm

Output: BNC, DC-Coupled

Rise/Fall Time1: 5ns

Bias: 12V Battery (Type A23)

Further specifications can be found in appendix 15.6

Where it is the spectral response, peak wavelength, and rise/fall time that are the deterministic parameters that tells whether the detector is suited for any given laser.

6.6.4 The beam dump

A 1x80x100 mm sheet of copper is bent in a 45 degree angle so that it can be strategically placed beneath the experimental setup to diverge the laser beam, hereby minimizing the risk of backscattered light from the surroundings into the detector.

6.6.5 The vision system

A vision system is used for as guidance when the laser is positioned relative to the experimental setup. This system consists of a computer with a USB webcam, positioned on the Z-axis of the NC system, overlooking the experimental setup.

6.6.6 The oscilloscope:

A Picoscope 3206, USB based oscilloscope is used to collect data from the detector. The same computer that drives the NC software and the webcam is running Picoscope 3206 through its driver- and monitoring software. This software gives the user the ability to capture datasets in a tab-delimited format which is cut n paste compatible with MS Excel.

6.7 Other equipment used during the initial experiments

An NC optical measuring device, the DeMeet, as well as a laboratory standard graded stereomicroscope has been used as well has been used to visually inspect the rod for vaporization damage and to check the surface roughness. Measuring tools as a Caliper Vernier and a micrometer clock has been used to set up the experimental rigging. A class I b, 4 mW red HeNe laser with a fiber coupling has been used to visually inspect the beam path throughout the experimental setup for alignment purposes.

6.8 Experimental approach

The initial experiments to replicate the beam analyzing method from 1983[1] was predominantly conduct to validate that the analyzing method. Some of the experiments though were conduct to validate theoretical calculations and theories such as the minimal rotational speed and the resolution calculations mentioned in chapters 6.5.

6.9 Experimental procedures

The NC and fiber laser system are powered up. A reference run is executed to home all NC axes, and the NC system are moved to the desired position.

A piece of aluminum TIG filler rod is cut and connected to the miniature dc motor via the axle fitting. The motor is bolted down to a plate, which is held in place by a vice grip. They are placed on the X-Y- NC plane directly beneath the laser optics. The dc motor is powered up and if needed the rod is balanced by adjusting its position in the fitting. The laser cabinet is closed, power output of the laser is checked and the laser is turned on. A small spot is seen on the vision system seemingly hanging in mid air as it hits the path of rotation of the rod as seen in picture 6.9.1

Picture 6.9.1 beam spot in mid air.

The Z-axis are tuned so that the spot visually is as small as it can be focused. Hereby the focal point is determined very roughly.

The detector are coupled to a 800 micrometer fiber through an SMA connector and the far end of the fiber are connected to a tube formed black anodized aluminum shielding. The aluminum shielding is fixated to a tripod with a clamp and placed at a roughly 45 degrees above the rotating rod. For alignment purposes the procedure above can be executed with the red HeNe laser attached to the optics instead of the Fiber laser. Hereby tuning of the setup can be performed with the doors of the laser cabinet opened.

Monitoring and measuring is performed by attaching the detector with a coaxial cable, and a 50 ohms terminator to the Picoscope. The Picoscope software interface is then ready to be used to capture sample data as tab delimited text.

6.10 Commonly routines and commonly used parameters:

For all experiments a few things must be determined for later use when the experimental data is being post processed. These are:

- The horizontal offset from the focal point of the laser to the center of revolution of the motor.

- The rotational speed of the miniature DC motor.

The following routines must also be performed before each experiment:

After a rough determination of the focal point, by using the method described in chapter 6.9, the horizontal position is trimmed by moving the X- and Y- NC axes while examining the detector signal intensity on the oscilloscope. This makes it possible to tune the X- and Y- axis so that the laser beam is placed where the signal is strongest. Now the laser beam is moved in the vertical direction (the Z axis) until the signal is strongest to determine the focal point more accurately.

When found, the laser is vertically placed so that the signal is strongest so that the focal point lies on top of the rod.

It is now time to determine the commonly used parameters. The rotational speed is first found. The Picoscope software is set up so the sampling range contains two signal peaks from the detector. The distance between these two peaks can now be measured. The value is noted so that it is available at post processing.

The other common parameter being the horizontal offset is now measured. The position of the NC table is noted. The NC table is moved so that the laser spot will hit the rotational center of the rod fitting. This is clearly seen as the fitting is turned on a lathe and therefore small groves in the surface from the machining process draws a spiraling pattern towards the rotational center. When the rotational center is found the new position is noted. By using trivial classical trigonometry the distance from the measuring point to the rotational center can now be calculated.

Finally the laser is moved back to the optimum signal position and the setup is ready to be used to conduct experiments. This position will in experiments 1-4 be reffered to as the initial position.

6.11 Experimental overview:

Experiments of interest are as following:

1) The collection of a data series by moving the laser in the vertical plane (NC z-axis) so that a beam propagation path can be calculated from the captured data.

2) Two collection of data series where the NC table first is moved in the X- and then in the Y- directions to determine the sensitivity of horizontal positioning of the beam.

3) The effects of the power variation of the laser by analyzing the detector output signal strength.

4) A collection of data series from different detector viewpoints to determine if the beam propagation is symmetrical.

6.12 Experiment 1:

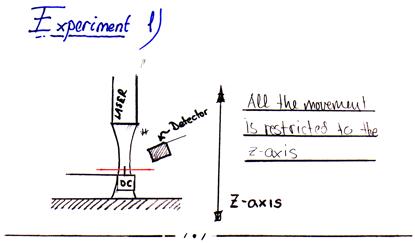

The first experiment conducted is the variation of the vertical position of the laser. This was done to be able to calculate a beam propagation path and to see if it was possible to determine whether the optical system was not askew. It is also this experiment that will tell whether it is possible to replicate the experiments from 1983 on the experimental setup. The task is therefore to capture sufficient data to calculate the beam propagation. Sketch 6.12.1 shows a diagram of the setup.

Sketch 6.12.1 Experiment one setup seen from side

The laser is placed in the initial position. The Z axis are moved down until the output signal of the detector is halved. This offset should place the focal point roughly the distance of the Rayleigh length above the experimental setup. The distance,- dZ, is noted

Next

is off course to perform a set of measurements. The laser is moved in its

vertical plane. A step length calculated by using the vertical offset, dZ, is

calculated by the equation: ![]() so

that the measuring series are finalized when the horizontal offset is +dZ. For

each step a scan over the detector is dumped from the oscilloscope to an MS

Excel datasheet.

so

that the measuring series are finalized when the horizontal offset is +dZ. For

each step a scan over the detector is dumped from the oscilloscope to an MS

Excel datasheet.

The data is finally saved in a tab delimited text format from MS Excel so they are ready for the data post processing.

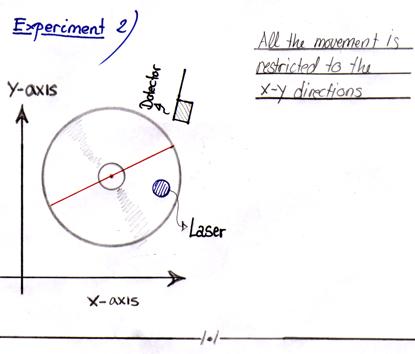

6.13 Experiment 2:

Preparations positioning of the laser beam follows that for experiment 1. One must first align and then find the focal point. However it is of interest of this experiment that after finding the focal point that the laser remains stationary in the vertical direction. Instead the rod is moved in the horizontal plane. Sketch 6.13.1 shows a diagram for this setup.

Sketch 6.13.1 experiment 2 seen from above

The laser is moved to the initial position. First the setup is moved in one direction e.g. the X direction until the intensity is roughly halved. Then the rod is moved to the original position and the experiment is repeated in the –X direction. This is also done for the Y direction. Data is dumped for each step, and the step length is determined as in experiment 1 so that 20 datasets are retrieved.

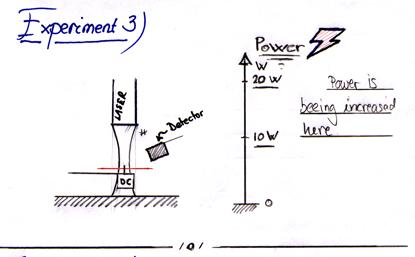

6.14 Experiment 3:

This experiment is to conducted to examine the linearity of the experimental setup in relation to the laser output power. The laser output is according to the manufacturer linear and testsheets delivered with the laser proves this. By analyzing the output of the detector by varying the power of the laser it can be analyzed ehether the detector and the rest of the experimental setup behaves linearly as well.

The laser is moved to the initial postion. Then a set of measuring data is captured and saved in MS excel for varying power settings starting at the maximum power output. After data series is collected power is turned 500 mA down, and the data captured again. This is done in repetition until the output power of the laser has been halved. A sketch of the setup is also provided for this experiment in sketch 6.14.1

Figure 6.14.1 experiment 3

6.15 Experiment 4:

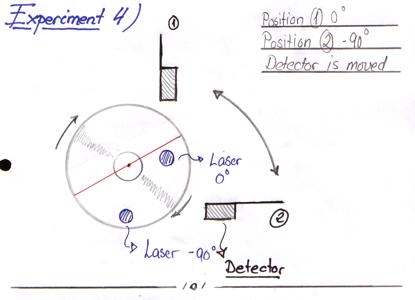

This last experiment is done to see whether the beam path is symmetrical around the axis of propagation. The experiment is actually a repeating of experiment 1, after which the experimental rig is turned 90 degrees after which the experiment is performed yet again. When the experimental data is processed it will be possible to compare the two calculated beam propagation paths against each other hereby and determine any irregularities of the beam path that might exist.

Sketch 6.15 Experiment 4 as seen from above

6.16 Data post processing

When a set of measurement data has been captured from the experimental setup it is necessary to perform several steps in a data post processing procedure. This will be carried out in MatlabÒ by MathworksÒ. This chapter describes how a beam propagation calculation is performed as in experiment 1 and 4 since this is the way the post processing will be performed when the final beam analyzer is constructed and a beam propagation profile is measured. Post processing of data in experiment 2 and 3 is done by only applying a certain part of the procedure described below namely the fitting of the captured data. A captured dataset describes the intensity profile through the beam and since this is assumed to be a Gaussian distribution for the fiber laser it is therefore fitted to match this. The complete step-by-step beam propagation data post processing as for experiment 1are therefore described in a general fashion so that it is not limited to the laser setup at IPL/CALM.

6.16.1 Needed data.

First of all the following parameters has to be found:

- Rotational speed of the rod.

- Horizontal offset from the measuring point to the rotational center of the rod.

- Wavelength of the laser, which can be assumed with reasonable precision.

The horizontal offset to the measuring point is best determined by using the lasers own horizontal NC plane if available. If measurements are performed on a laser that cannot translate in the horizontal plane, it is easy to determine the distance by powering off the miniature motor, and fixating a small sticky-note on the rotor. Now a small hole can be machined in the paper with the laser and the distance from the hole to the rotational center is measured with a Vernier caliper. Hereby the distance in mm. can be determined with at least one decimal.

6.16.2 Determining the Gaussian.

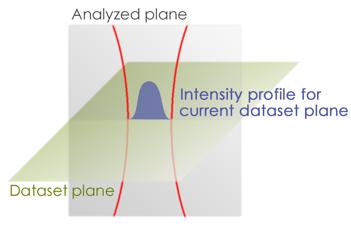

The sample data for a measurement series consist of several datasets measured with different vertical offsets relative to the assumed focal point of the laser. A dataset corresponds to a scan of the laser beam over the detector in a horizontal plane and is a two dimensional measurement in a vertical plane.

Figure 6.16.2.1 Overview of the planes of described in the procedure

Each dataset captured consists of a 2xn matrix where n represents the number of sample points in each dataset. The first column of data is the time in nanoseconds at where the data point was registered by the scope, and the second column is the signal voltage that describes the relative intensity of the laser at that point in time. This intensity is for fiber lasers expected to be a Gaussian distribution.

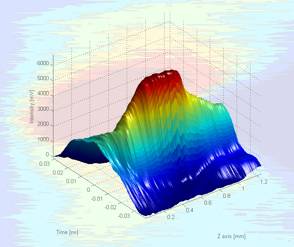

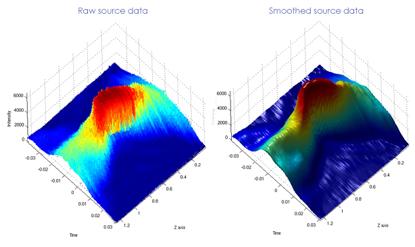

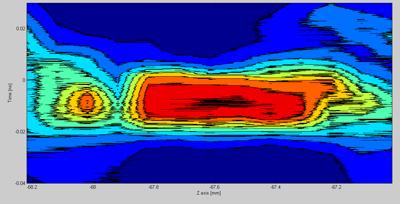

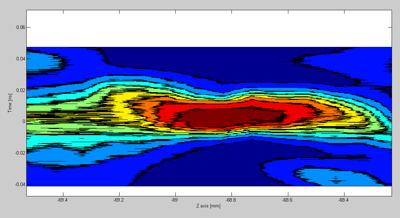

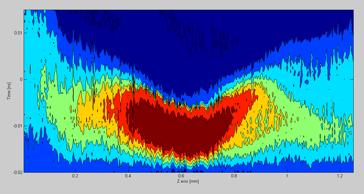

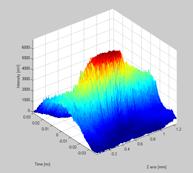

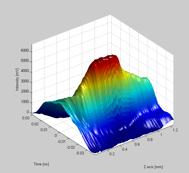

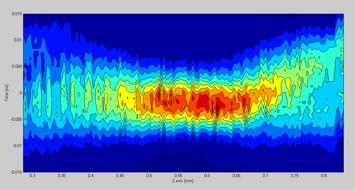

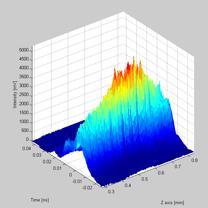

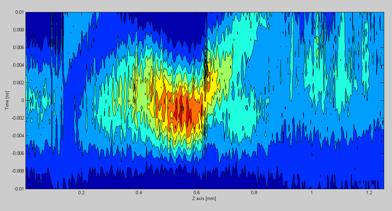

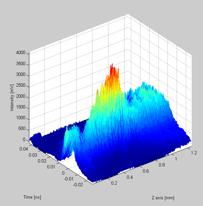

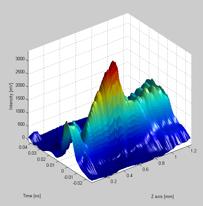

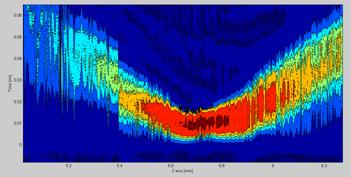

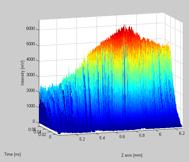

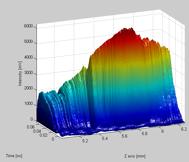

The raw source data are plotted as 3D and a 2D graph with color gradients representing intensity for the user to inspect before the matlab script continues. The picture below shows a beam propagation graph in 3D. As it clearly can be seen, applying different levels of smoothing and lighting effects can help during the inspection of the source data.

Figure 6.16.2.2 A 3D image of the beam propagation

After plotting the graphs, the time axis is converted to distance using the parameters of rotational speed and the distance from the measuring point to the rotational center. Hereby the intensity at the laser versus the distance from the center of the beam is known in all the datasets each representing a horizontal plane

As each dataset is expected to be a Gaussian distribution they are now being approximated with a nonlinear least-squares regression fitting algorithm that returns four deterministic constants for the Gaussian expression[15]:

![]() (Formula 6.16.2.1)

(Formula 6.16.2.1)

Where:

b1 - is the relative intensity

b2 - is the waist of the Gaussian distribution

b3 – is the offset

b4 – is the background/ the low signal

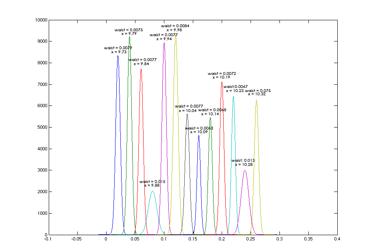

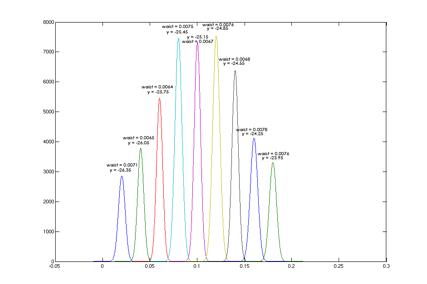

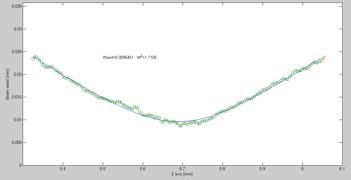

The outcome of the fitting procedure can be visualized graphically as seen in figure 6.16.2.3:

Figure 6.16.2.3 Raw source data with fitted Gaussian curves.

When the fitting algorithm has ended each dataset is now replaced by a Gaussian expression with varying constants and are saved to a text file on the computer containing a 5xn matrix with the first column containing the relative z-height, and the last four columns contain the above constants. This is done because the calculations so far are heavy to compute, and require full CPU time for several minutes. The rest of the calculations can at this way later be run separately to review the results of the calculaions.

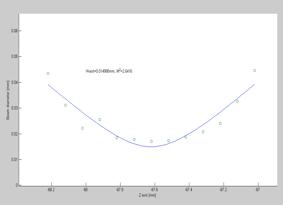

6.16.3 Calculating the beam propagation path.

The data that was saved as output when the source data was fitted to the Gaussian expression is loaded. The first and third column of these source data being two 1xn column vectors containing the relative z height of the dataset and the waist of the Gaussian distribution are used to perform another nonlinear least-squares regression fit.

This time the Gaussian waist are interpreted as the beam diameter at a given z height, the sideways offset is normalized, and the fitting algorithm is performed on a formula that is derived based on another well known formula from laser optics. It is the formula that describes the beam diameter as function of the beam path.[16]

The derived formula has the following appearance:

(Formula 6.16.3.1)

(Formula 6.16.3.1)

Where:

b2 - is the beam waist (Smallest beam diameter)

b3 – is the M2

b4 – is the waist position

l - is a constant containing the wavelength of the laser

z – Is an offset constant in the direction of the beam propagation as the formula requires that the y axis is placed at the beam waist.

When the fitting algorithm is finished, it returns the numerical determined waist and M2 that matches the measurement data and finally a 2D graph is plotted that shows the beam propagation with the x-axis as symmetrical axis through the center of the beam path.

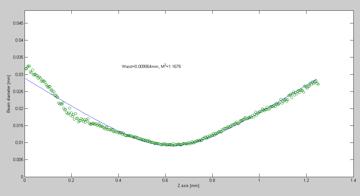

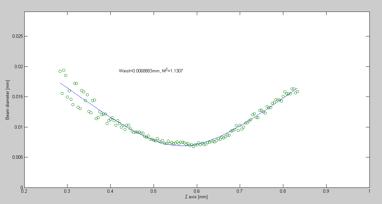

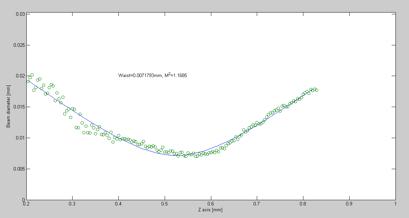

Figure 6.16.3.1 Beam waist and M2

6.17 Presentation of data from the initial experiments.

6.17.1 Experiment 1.

Experiment 1 was intended to be a proof-concept experiment. Experimental data was processed by the MatlabÒ post processing algorithm.

It was shown that the experimental setup from 1983[1] had been successfully replicated and that it was possible to calculate a beam propagation path with, M2 and the beam waist in mm.

Graph 6.17.1.1. Showing beam waist [mm], M2 value and propagation path.

6.17.2 Experiment 2.

This experiment was intended to show the influence of offsetting the experimental setup in relation to the laser. It was done to examine how important it is to align the beam analyzer correctly under the laser. The graphs below shows the Gaussian waist as well as the intensity (not to confuse of the beam waist) of data series sampled from the Picoscope. As the intensity of the signal in mV is a relative factor describing the energy distribution of the spot it is not as important as the Gaussian waist, which is needed to be roughly the some for the offset to be unimportant.

The first dataset to be presented are the data for variations in the x-direction. This corresponds to changing the measuring distance from the rotational center of the experimental setup.

Graph 6.17.2.1 Showing Gaussian fits with intensity [mV] in the vertical direction

A totally random intensity pattern is seen for the intensity signals. This seems to be related to the surface quality of the reflecting rod, where high intensity is obtained where the surface is even and low intensity is related to scratches and imperfections in the surface of the rod.

Since the intensity of the signal describes the intensity of the laser in a relative manner, this behavior might only to some extent affect the signal. Another important parameter is the waist of the Gaussian distribution that is used to describe the beam diameter. These values must not deviate as much and as randomly as is the case with the intensity. The Gaussian waist as a function of dX distance is plotted to observe this and as expected the waist is close-to constant. The added trend line shows a slightly falling beam waist as the measuring point are moved further out the rod. The falling tendency is only around one mm and more deep analysis must be performed the show if this is due to deviation or a true tendency.

Graph 6.17.2.2 The

Gaussian waist as a function of X direction

Graph 6.17.2.2 The

Gaussian waist as a function of X direction

The same two graphs has been made for varying Y offset. This direction is perpendicular to the rod when it is struck by the laser light. If the measurement point is offset in this direction it will mean that the plane in which the reflected laser beam is scanned will be at an angle to the detector.

This can be critical when a fiber is used to collect the laser beam since a steep interaction angle to the fiber can result in what is known as cladding mode[Chapter 11.4]. It will also affect the intensity of the collected signal and Gaussian waist as follows.

Graph

6.17.2.3 Showing Gaussian fits with intensity [mV] in the vertical direction

Graph

6.17.2.3 Showing Gaussian fits with intensity [mV] in the vertical direction

It is clearly seen that the intensity of the Gaussian waist is a function of Y offset and hence the interaction angle of the collecting fiber of the detector As with the X-series this can be ruled irrelevant and the most important analysis is if the beam waist is affected.

Graph 6.17.2.2 The Gaussian waist as a function of Y direction

The trend line again shows that there could be a rising tendency of approximately 1 mm. This cannot be ruled out to be deviation.

6.17.3 Experiment 3.

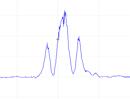

This experiment, which is the simplest of the latter, was intended to show if the experimental setup behaved linearly in relation to lasing power. The fiber laser from the IPL/CALM behaves absolutely linear in relation to the applied current. By changing the output current of the laser it was therefore possible to see if the experimental setup had any unexpected nonlinear effects.

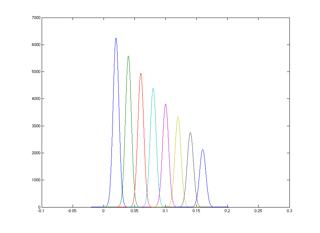

Graph 6.17.3. Signal intensity VS. power. Horizontal axis [mV]

The graph show the signal strength in mV with the intensity falling from full output power at 20W with a current decrease of 500 mA pr. step.

It is clearly seen that the experimental setup act linear and as expected that no nonlinear effects shroud cause worries throughout data processing.

6.18.4 Experiment 4.

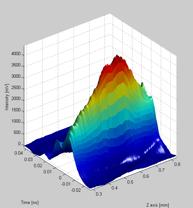

The final setup was intended to show if the beam propagated uniformly. Data captured from the experiment is shown below.

Figure 6.18.4.1 It is clearly seen that the beam propagates differently in the two planes

As seen on figure 6.18.4.1 the beam seems to propagate differently in the two planes. The beam waist can just from examining the raw data, be seen to differ from the two planes of investigation. This means that the measurement data tells us that the beam spot has an oval shape. The difference in z-axis values is due to the rearrangement of the setup and should be neglected.

Figure 6.18.4.2 The beam propagation calculation. The difference in propagation path is obvious

The beam propagation paths for the two measurements also clearly shows a difference in the way the beam propagates throughout the planes. Due to the limited amount of data points is difficult to say whether the very two beam propagation calculations are so very different in reality of whether it’s a bad case of deviation. The difference is so big though that a difference in propagation pattern in the two planes in some degree must be to blame.

6.18 Conclusion of the initial experiments

The method of beam analyzing from 1983 has been verified. Even more important is the fact that it has been proven that the method of beam analyzing from 1983 has the potential to be adapted and integrated to new and very strong numerical tools, when applied reveals much more information of the laser beam than what could be retrieved from the experimental data in 1983. Roughly speaking, it was only possible to monitor the intensity profile, compared to now where a full beam propagation path can be estimated.

Alignment sensitivity has been determined not to be to sensitive in both X- an Y- direction. A positioning with an accuracy of 0.1 mm seem be enough, and is an important factor in the upcoming design and development of the final beam analyzer. This means in other words that any NC based laser with an axial precision of 0.1 mm or better will be compatible.

Yet another great thing visible from the initial experiments is the fact that the system as a whole acts in a linear manner. This makes interpreting the experimental data much easier.

Finally it has been proven that it is possible to determine how the beam propagates through different cross sections of the laser beam. In experiment 4, the beam path at two perpendicular measurement points were held together to give a more detailed view of the laser beam. This method could be expanded to actually generate a 3D propagation graph based on data collected all the way around the laser beam.

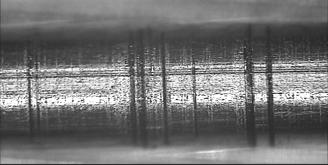

During the experimental work it was experienced that the miniature DC motor had to be run at its maximal rotational speed to avoid vaporization damage of the rod from the laser beam. The damage can easily be seen on picture 6.18.1, and needs to be addressed during the design of the laser beam analyzer.

![]()

Picture 6.18.1 Vaporization pattern, 10,000 RPM, Aluminum

It was experienced that a limiting factor throughout all the experiments was time. Collecting data manually took much longer time than expected which limited the amount of sample points and hence the resolution of the post processed.

This is another important discovery that must be addressed when designing the beam analyzer. It is of greatest importance that an automated data capturing process is developed. An experiment taking 2-3 hours to conduct could in best case be conducted in a matter of minutes if the entire process can be automated

7. Designing the beam analyzer.

The preliminary experiments have provided valuable experiences that will be used within the designing of the beam analyzer. The experiments define further demands and requirements that need to be abided for the beam analyzer to perform as desired.

These demands and requirements as well as the demands stated in chapter 3 was used to make a detailed system requirements outline.

The new set system specifications to be met are:

- Capable of measuring spot size down to of 10 µm.

- A horizontal measuring resolution down to of at least 1 µm.

- Maximum 70 mm clearance from the substructure to the laser nozzle.

- The analyzer must be able to collect data autonomous

- The revolution speed range of the rod must be from 7000-40000 RPM to accommodate more powerful lasers than the one used for the experimental work

- Inline monitoring module for motor RPM.

- The replacement of reflector rod must be easy.

- Vibrations in the structure must not be visible on measurements performed with a micrometer clock.

- Budget must not exceed 2,000 $

Final tests on the beam analyzer after it has been built will show if these demands have been met.

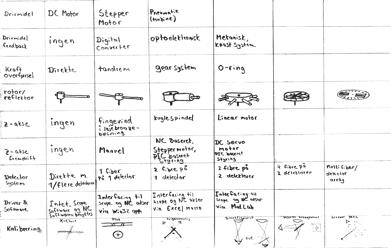

7.1 The first design concepts:

In the design phase one must consider following:

1) Specification requirements

2) How simple can the system be made

3) What does the system need and what would just be nice to have in the system

With those factors in mind one can use a simple morphology table to create a series of possible solutions to the design. To create such a table, one must first identify the sub systems. The beam analyzer has for the morphological analysis been broken down to the following sub systems:

a) Propulsion for the reflector rod

b) Propulsion feedback

c) Transmission

d) The reflector rod(s)

e) Vertical axis

f) Propulsion for the vertical axis

g) Detector system(s)

h) Possible use of drivers and software

i) Calibration aiming aids for the system

Only after these systems have been identified can a morphology table be created. Each system will have a number possible of solutions attached to it as seen on figure 7.1.1

Figure 7.1.1 Morphology table

What this table does is giving the developer the ability to create random solutions by going down the table and choosing what seem to be compatible subsystems.

Some of the more ore less random generated solutions will not be very good but most of them would comply with the specifications and do deserve a second look.

After narrowing the solutions down to 4 or 5, then one must look at the positive and negative sides of the solutions that are left. An good way of handling this so is to grade the solution and subsystems. The one with the highest overall score will likely be the final concept.

All subsystems of the candidate systems has been graded. Some of these subsystems are e.g. the reflector rod system, detector systems, the data collection rate, manually vs. automated alignment and calibration methods, their complexity, et cetera.

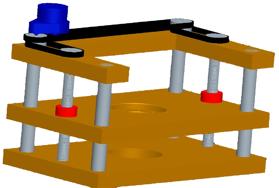

The first concept was based on a box-like structure. It was possible to control the vertical movement by implementing a stepper motor control. Also it was sufficiently compact to be positioned underneath most lasers. A table would be moved vertically up and down and in the centre of the plate there would be placed a turntable on which would host a subsystem consisting of the reflector rod and motor. This turntable could be rotated so that the laser beam could be monitored from different angles. Figure 7.1.2 is a CAD generated image of the first concept.

Figure 7.1.2 CAD drawing of concept no. 1

The system demanded two spindles. They would be required to turn at the same speed and at the same time a transmission of sort was demanded. A belt drive was the obvious solution since this would synchronize the two spindles.

This concept was rejected though. The rods supporting the structure that also served as guide rods caused concern. The structure was designed like this to provide the most stable possible but if any of the four guide rods were to be misaligned it would potentially cause the whole system to get stuck. Also it was much to complex to build within the timeframe available.

However some of the ideas found in the first concept are also to be found in the final concept. The central table, spindle, and the turntable for holding the detector/rod were kept. The way they were constructed and assembled can be found in the following chapters.

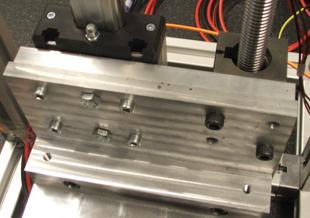

7.2 The final design:

The final design would be a scaled-down system similar to the previously presented rejected design. An inverted T-frame structure will be the structural skeleton and hold a linear rail an a ball screw spindle. Attached to these is a base plate that holds the analytical arrangement consisting of the reflector rod, rod motor, a fiber holder for the attachment of the detector and an optocoupler to count the revolutional speed of the rod. All part that needs to be manufactured will be made of aluminum alloy due its good machineability. All CAD drawings can be found in appendix 15.9 as well as on the documentation CD-ROM, appendix 15.1.

Figure 7.2.1 CAD drawing of the stepper motor controller

7.2.1 The turntable and horizontal plate

For making 3D beam analysis the beam reflector and collector system is mounted on an NC milled turntable with a fixed 30 degree indexing system. This gives the beam analyzer the ability to be used to analyze the beam at every 30-degree angle around the path of propagation. The turntable will rest on a ball bearing that provides rotational movement. This again will be mounted in a horizontal plate that holds an indexing bolt. The components mounted on the turntable are a brushless miniature motor with reflector rod and fitting, an optocoupler and a detector fiber holder. In the center of the turntable a hole will be drilled to serve as beam dump and the turntable itself will be painted with an opaque black paint near the beam dump.

7.2.2 The ball bearing unit

To be able to rotate the turntable, a suitable rolling bearing unit was needed.

The task is to find a ball bearing unit where the inner diameter is large enough to accommodate all the necessary components that must be fitted into the turntable. The minimum inner diameter had to be more than 90 mm. The type of ball bearing that meets these demands is known by the name, thin-ring bearings.

The type of unit chosen is not a standard ball bearing. Luckily thin-ring ball bearing is frequently used in the robotics industry. The robotic industry requires ball bearing units with a large outer and inner diameter, and with a small width. They are used in multiple-joint robotic arms, and fortunately such a ball bearing had the dimensions that was sought and was available on request[Appendix 15.7].

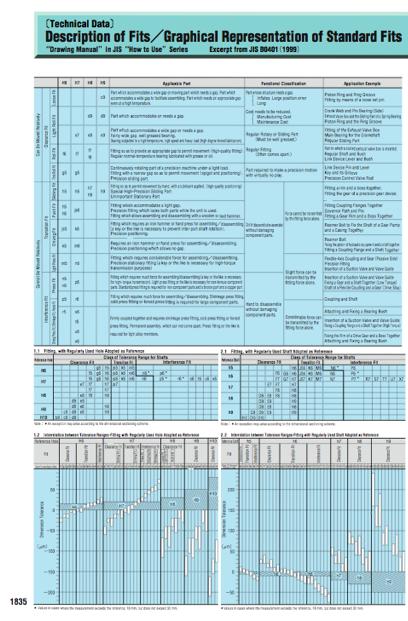

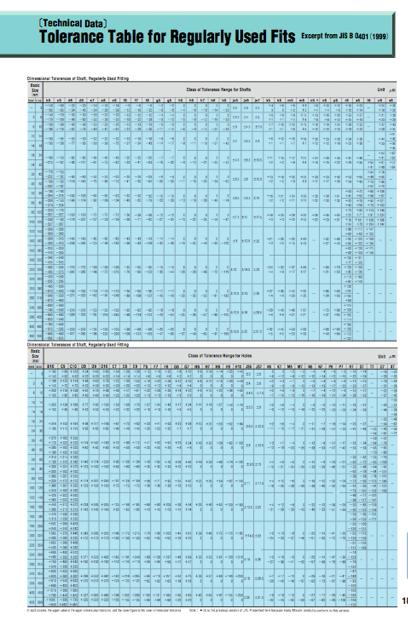

The tolerances of the bearing unit must be examined as well, so that the fitting of the bearing in its socket is a tight fit without any traceable sideways slack that might influence the alignment of the turntable.

The tolerances needed to make this a tight fit were found using an ISO tolerance table which can be found in appendix 15.10. A tolerance of this kind is of the type called a shaft/hub connection.

The tolerances of the bearing unit are provided by the manufacturer. What more is needed are the tolerances for the machined parts that will be fitted to the ball bearing. These are the turntable and the horizontal plate. In one case the bearing unit will function as a hub and in the other as a shaft.

The reseller of the bearing has specified the tolerance of the inner diameter to be 0 to -18 µm and of the tolerance of the outer diameter to be 0 to +20 µm. Using this information and the table, the following tolerances were found chosen to provide a tight fit with no traceable slack.

a) To ensure that the tight fit with the plane is achieved the diameter of the hole machined into the plane must have the ISO standard tolerance P7, which is a tolerance specified to a hub and defines a deviation of maximum -59 µm and minimum -24 µm.

b) The turntable must be machined to following specifications and tolerances, namely n7 which is a tolerance specified to a shaft, and has a deviation of minimum 23 µm and maximum 58 µm.

These tolerances will give an extremely tight fit. It will not introduce any assembly problems since the diameters are large compared to tolerance ranges, and due to the fact that the fit is aluminum vs. the hardened steel of the bearing. Due to the tolerance requirements, the turntable and the plate is machined in a CNC controlled milling machine.

7.2.3 The back plate

The plate in which the turntable rests must be mounted on the spindle and rail system. Mounting the turntable plate on a vertical back plate does this. The vertical back plate also serves as a linkage between the ball screw and rail system. A rectangular shaped aluminum block is used as support between the turntable plate and back plate. This block helps alignment of the turntable plate in the horizontal position.

Figure 7.2.3.1 The back plate. The support block can be seen in the lower part of the picture.

7.2.4 Reflector rod holder

It is very important that the reflector rod is rotating in a plane perpendicular to the laser beam. This is achieved by fabricating a holder for the reflector rod with very tight tolerances.

Fabrication itself demands that threads of varying diameters can be fastened to the holder. Also the material used for the holder must be very light to prevent a vast current drain as the motor is started. Finally it must be easy to machine. Obvious choice is aluminum alloy since its light weight and due to the machinability of the alloy.

Figure 7.2.4.1 Reflector rod holder

The holder is machined out of a solid aluminum rod. This rod will be turned with a lathe, which will machine it down to the specified dimensions in one clamping, to provide maximum rotational symmetry. A milling machine is used to cut a groove in which the reflector rod will be positioned and fastened.

7.2.5 The reflector rod

The reflector rod may be interchanged with rods of varying in diameter due to the relation between rod diameter and resolution as explained in Chapter 6.4. What is of great importance is that it is as perfectly round as possible, and that the surface quality is as good as possible.

This can be achieved by extensive polishing of the surface or by surface treatment. The rod can be copper plated, or even plated with silver or gold. This enhances the rod in two ways. Foremost a material with good reflectivity can be plated to enhance performance at any given wavelength, and also a plating process will smooth out scratches and grooves on the surface of the rod. If the surface quality is so good that the scratches are below the wavelength of the laser they are not interfering with the reflected light[17]. Such scratches are called subwavelength imperfections.

A test has been conducted on a Wolfram rod with a diameter of 3 mm. This type of rod what is normally used as an electrode for TIG welding, and can withstand temperatures in excess of 3000˚C. It has a limited reflectivity at the wavelength of where 1075 nm where the test were conducted.

It was thought that the high melting point might rule superior to the reflectivity parameter. The reflectivity proved more important though. The laser simply began to cut grooves into the rod material. This can be seen on picture 7.2.5.1.

Picture 7.2.5.1 Cuts made by the laser beam in the Wolfram rod

Experimental work has also shown that an ordinary aluminum rod seems to be good enough for the purpose of testing and validating the laser beam analyzer so an ordinary aluminum TIG filler rod will be used as reflector rod, and can easily be upgraded in future development.

7.2.6 The inverted T-frame skeleton.

The frame must be strong, durable and most of all straight. Like the plane and the rod care must be taken when the frame is assembled to make sure it is straight. The best way of ensuring that the entire structure does not sway is to construct the base of the frame as a tripod. Hereby 3 points of the frame is in contact with the ground at any time.

The frame itself is constructed in a standardized extruded aluminum profile system developed and produced by the German company, Bosch Rexroth. The profile is bought as one long extruded profile, and can then be cut to lengths that will be in the construction of the frame.

The profiles needed for the construction of the T-frame are listed in appendix 15.8 and are cut a few millimeters longer than the desired length. After that the last few millimeters are removed by milling them down to size. The milling process insures that the cut surfaces are perpendicular to the profile and when assembled the frame will be as straight as possible.

Figure 7.2.6.1 Bosch Rexroth profile system.

To make the assembly job easy, Bosh Rexroth sell prefabricated squared joints so that the frame can be assembled with only two bolts pr. joint. These joints come in different shapes and sizes so depending on the type of assembly it is possible to find a joint that suits the purpose.

7.2.7 Spindle and linear motion rail

Vertical motion is made possible by using a ball screw and a linear rail system. These components are standard components and are readily available on the market. The ball screw and rail system that were utilized were unused part lying in the ILP/CALM laboratory and probably their origin is unknown. This is also the reason why the NC axis of the beam analyzer seems to be over-dimensioned.

The rail system is used to stabilize the vertical motion and as a support for the back plate. This will ensure that there is no sideways slack in the system that can tilt the entire system to one side. The ball screw provides the system with a likewise vertical stability limited to the spindle slack.

The ball screw has a 2.5 millimeters gradient. This means that by turning the ball screw 360 degrees one gets a horizontal movement of 2.5 millimeters. It is fastened to the frame by the means of two ball bearings in two flanged bearing housings.

Figure 7.2.7.1 The bearing flanged housing

The advantage of such housings is that any misalignment between the ball screw and linear rail easily can be balanced out by the following routine. The ball screw and linear motion rail are loosely fixated on the back plate. The ball screw and rail are moved to the downmost position. The lower flanged housing are bolted tightly to the frame Then the spindle and rail system moved to the upmost position and the upper flanged housing are bolted tightly to the frame. Now the back plate are boltet tight and everything is aligned properly.

7.2.8 Strength of the turntable plane

Since the final design of the beam analyzer is based on a free hanging plate it is important to investigate whether this construction will pose any problems related bending. The plate cannot during the experiment be allowed to bend downwards. Reason being that the plate is wanted to be perpendicular to the laser beam. Considering the design of the plate and its support, simple calculations can prove if the plate will bend and if it is a cause of worrying.

The setup has been simplified into a situation for which there exist equations for bending and loading. The drawing bellow illustrates the situation in its simplified form.

Figure 7.2.8.1 Loading situation for the plane where the arrow indicates the center and direction of the load force.

A set of equations from the classical beam theory can be used to calculate the bending under this type of loading[18]. The load comes from the planes own weight and the weight from the turntable holding the instruments. So knowing the materials used in creation of the components it is possible to calculate the load using Newton’s second law of motion:

![]() (Formula 7.2.8.1)

(Formula 7.2.8.1)

In this situation the acceleration is the force of gravity and the mass is mass of the turntable and plate system. In the worst case assumed that the plate and turntable will have a combined total weight of 5 kg. The force or load acting on the plate is then calculated to be 49.1 N.

The position of the load is usually put in the middle of the plate where the centre of gravity is assumed to be. However in this situation the loading will not occur in the middle. Reason being that the largest concentration of mass will be offset towards the end from the middle of the plate. Here it is very important to know all the dimensions.

The equations that describe the bending can be seen as formula 7.2.8.2. These equations are derived from beam theory, but can be applied in this case due to the fact that the plane acts as a beam, and the forces involved are not severe.

(Formula

7.2.8.2[18])

(Formula

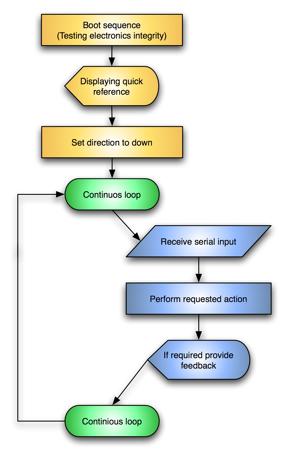

7.2.8.2[18])